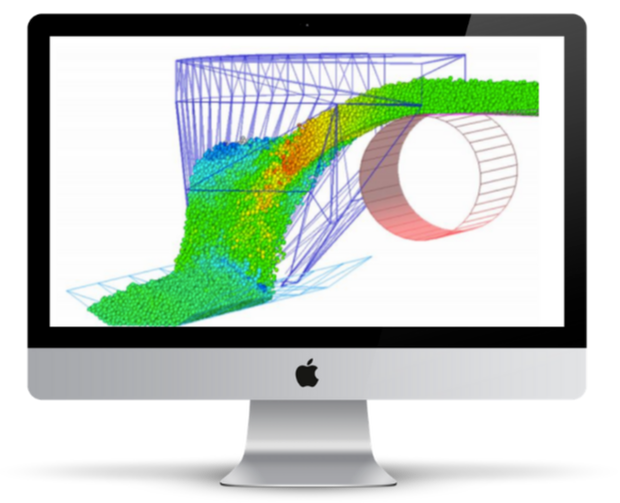

Discrete Element Modelling is used to approximate the motion and mechanical interactions within a system. This is

achieved by simulation of the bulk material as a discontinuous system of particles within the physical constraints of

interest. The simulation then provides a detailed description of the velocities, positions, and forces acting in the system

throughout the entire analysis.

achieved by simulation of the bulk material as a discontinuous system of particles within the physical constraints of

interest. The simulation then provides a detailed description of the velocities, positions, and forces acting in the system

throughout the entire analysis.

Why DEM?DEM allows for designs to avoid typical problems such as plugging, dust creation, material degradation, premature belt and chute wear, and off-center belt loading. DEM is a tool used to allow visualization of

a variety of loading scenarios, such as upset conditions and various flow rates prior to fabrication. This approach is used to eliminate the traditional approach of trial-and-error testing, saving on fabrication costs while provided improved system operation. |

APPLICATIONSDiscrete Element Modelling can be applied to any system containing bulk materials. This includes but is not limited to:

|

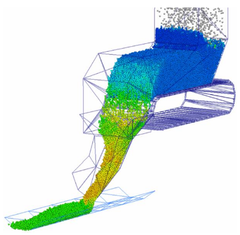

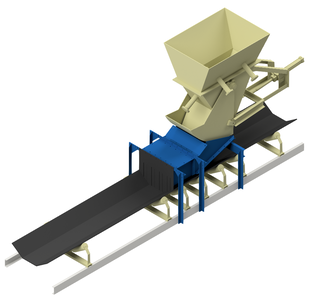

Granular Reclaim Chute

|

Scope of project involved evaluating the design of a transfer chute designed by others (prior to fabrication and install). The new transfer point had to fit within a confined space and discharge onto a steep angle (~17°) conveyor that is oriented at an angle (plan view) greater than 90° from the belt conveyor discharge direction.

The project scope included the following:

|

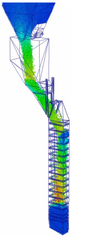

SKIP LOADING STUDY

PRODUCT STORAGE CHUTE REDESIGN

|

The existing transfer points allowed product to freefall from one conveyor to the next. This resulted in dust creation and material spillage in a small and difficult to maintain area.

New deflectors and bottom chutes were added. This minimized dust creation and product spillage. The project scope included the analysis of product flow through the existing chute system, design of chute inserts to keep fabrication costs low and to minimize the amount of field work required for installation, and new skirting design. |

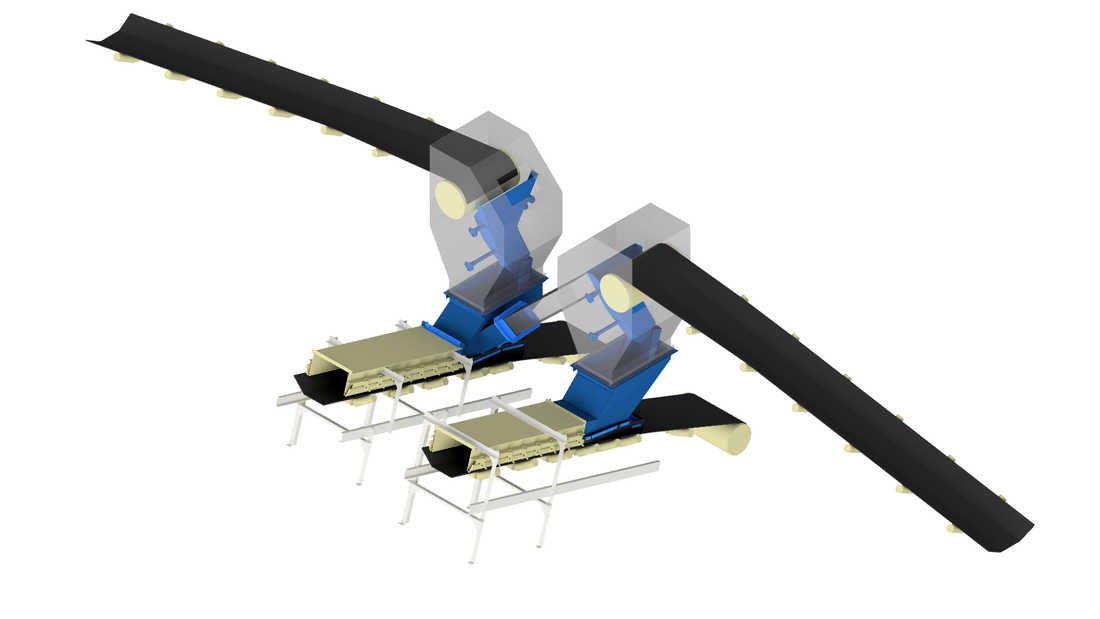

RECLAIM GATE REDESIGN

|

This goal of this project was to increase the flow capacity through the reclaim gates from 700 tph to 900 tph while also reducing dust creation and product spillage. Initial thoughts were that larger grizzlies, chutes, and gates would need to be installed which would require significant concrete and steel modifications as well as extended down time and more complicated installation and safety issues.

Flow simulations allowed us to determine that the existing gates could be slightly modified and reused when paired with a new loading chute and skirting design to achieve the desired flow rate. With over 20 gates on the length of the conveyor there were significant financial savings by avoiding the installation of larger equipment. |